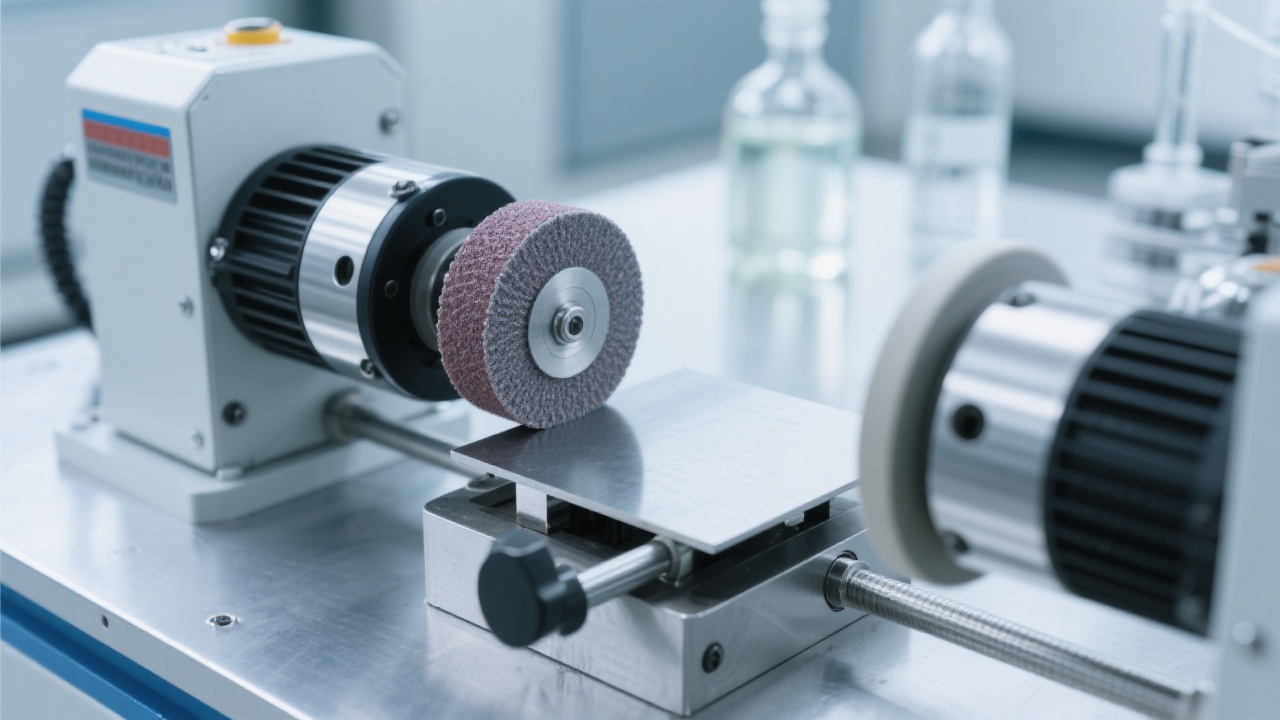

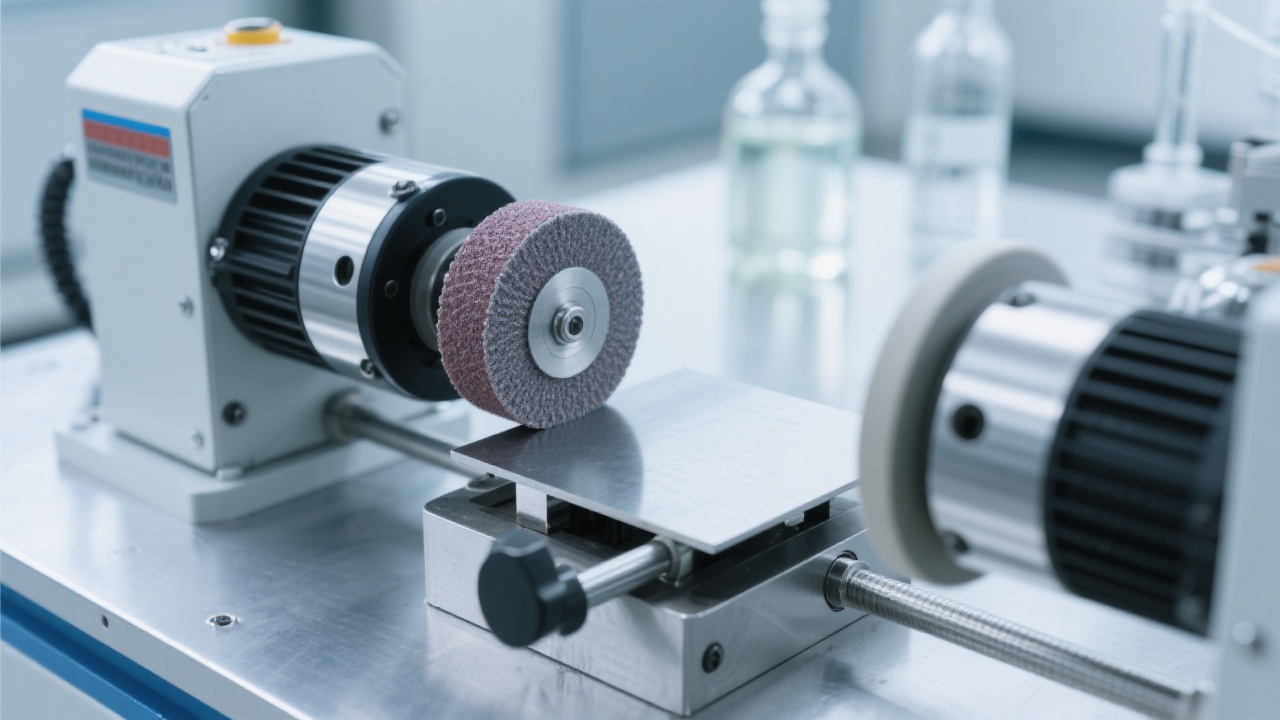

How Incorrect Sample Cutting Machine Selection Drives Up Rework Costs: A Real-World Industrial Case Study

This article explores the critical impact of improper sample cutting machine selection on manufacturing efficiency and cost, highlighting a real industrial case where neglecting key parameters such as cutting diameter, power transmission capacity, and cooling system performance led to frequent sample damage and escalating rework expenses. By analyzing technical specifications and contrasting equipment requirements across metal and non-metal sample preparation, the article guides procurement decision-makers to avoid common pitfalls. Practical evaluation checklists and material-specific grinding wheel matching strategies are provided to help companies reduce losses, enhance cutting quality, and optimize production workflows.

From Misguided Selection to Efficient Production: A Real-World Analysis on Sample Cutting Machines

Have you ever experienced the frustration of costly reworks or sample damage during your industrial sample preparation? The root cause often lies in selecting a sample cutting machine that doesn’t meet the specific technical requirements of your application. This article dissects how overlooking key parameters such as cutting diameter, power transmission capacity, and cooling system efficiency can trigger a cascade of production bottlenecks leading to increased downtime and rejected samples.

Key Technical Parameters That Impact Your Cutting Efficiency

The heart of an efficient sample cutter lies in its technical specifications. Let's break down the essentials:

- Cutting Diameter: This determines the maximum sample size and influences how delicately the material is cut. Machines with incompatible diameters can cause uneven edges, leading to sample damage.

- Power Transmission Capacity: Insufficient torque or inconsistent power delivery can cause blade stalling, resulting in prolonged cutting times and defective samples.

- Cooling System Efficiency: Proper cooling prevents overheating of the blade and specimen, reducing the risk of thermal deformation and extending the equipment's lifespan.

- Abrasive Wheel Type: Selecting the correct grinding wheel based on sample material ensures optimal cut quality and longevity of consumables.

Diverging Needs: Metal vs. Non-metal Sample Cutting

Different industries impose distinctive demands on cutting equipment:

| Industry |

Key Parameters |

Typical Challenges |

| Metal Processing |

High power transmission, robust cooling, and diamond abrasive wheels. |

Blade wear, overheating causing sample warping. |

| Non-metal Inspection (e.g., ceramics, polymers) |

Precise cutting diameter control, gentle torque, fine-grain abrasive wheels. |

Chipping, cracking, and inconsistent edge quality. |

Understanding these differences enables targeted equipment selection that aligns with your material properties and downstream processes.

Case Spotlight: How Ignoring Cooling System Design Nearly Halted Production

One manufacturing company faced recurring stoppages due to their sample cutter overheating—a result of an inefficient cooling mechanism. The frequent thermal stress caused blade fractures and sample surface cracks. After implementing a cooling system upgrade that reduced downtime by 50%, the company noted a 30% improvement in yield and minimized sample rejections.

Your Practical Evaluation Checklist: Five Steps to Assess Cooling System Adequacy

- Measure average operating temperature during cutting – is it within manufacturer’s specs?

- Audit coolant flow rate and pressure to ensure consistent heat dissipation.

- Inspect for signs of coolant contamination that could impair performance.

- Evaluate maintenance frequency and system cleanliness to avoid blockages.

- Test cooling system alarm or shutdown triggers for early fault detection.

Complement this by choosing abrasive wheels matched to your sample’s hardness and fragility. For instance, fine-grain wheels excel in cutting brittle materials with minimal chipping.

Take Action: Diagnose Your Sample Cutting Risks Today

Are you facing unexpected sample rejections or equipment downtime? Have you thoroughly evaluated if your sample cutter's parameters align with material and process needs? Conducting a structured self-diagnosis can unlock significant savings and streamline your production.

We invite you to share: What has been your biggest challenge with sample cutting equipment? Comment below and connect with a community navigating similar issues.